Bulkhead Repair

A Pier for any Storm

November 29, 2023Common Bulkhead Repairs

Bulkheads are a part of waterfront living. They protect your land from erosion and they give you water depth right at the shoreline, they are not a permanent structure and they eventually need repair or replacement. Today, we will explore some of the common problems bulkheads have and how they can be repaired.

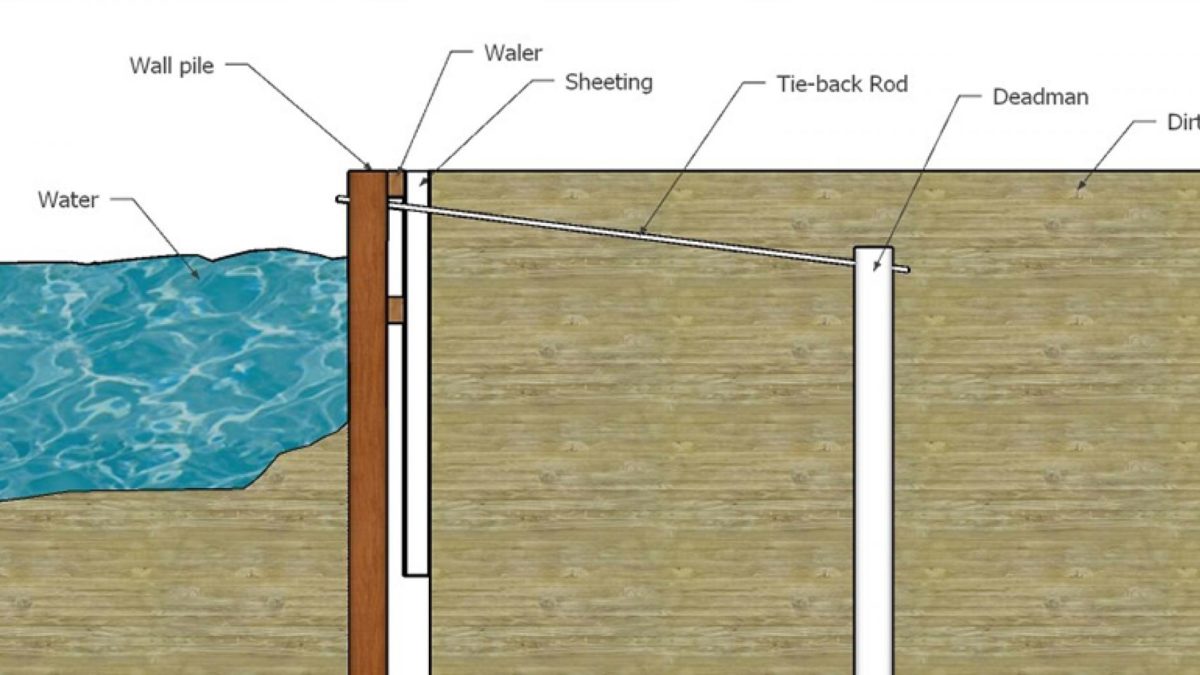

First, let’s look at the typical components of a bulkhead so we can understand their function and potential problems. As you can see from the diagram, the components are:

1. The wall piles. These piles are longer than the sheeting and from a main structural component. Damage to piles cannot be repaired, but the piles can be replaced.

2. The Waler. Another major structural piece that bridges the piles together into a wall. Damage to walers cannot be repaired and walers cannot be replaced.

3. Sheeting. The sheeting is not structural and merely serves as a “dirt seal”. Wood sheeting is typically the first component to have problems. Some steps can be taken to repair the sheeting.

4. Tie-Back Rods. Main structural anchor for the wall. The Rod anchors the top of the bulkhead to another pile behind the bulkhead. This is a critical part of the bulkhead and is replaceable.

5. Deadman. This is the anchor pile which is driven into the ground usually 10-12ft behind the bulkhead. This pile is replaceable if it shows signs of rot.

Sinkholes

One of the most common problems I run across is losing land behind the bulkhead. Basically, your bulkhead is “Leaking” dirt. If the sheeting is wood, most of the time you have either a gap in the sheets or a hole has rotted out. In both cases, some steps can be taken to mitigate the leak or to repair it. If you have many sinkholes behind the bulkhead it might be time for a major repair. If you just have a couple, there are some steps you can take to put off the major repair for a while. The first thing you have to do is locate the hole or gap. Once you find it, here is what you do.

One of the most common problems I run across is losing land behind the bulkhead. Basically, your bulkhead is “Leaking” dirt. If the sheeting is wood, most of the time you have either a gap in the sheets or a hole has rotted out. In both cases, some steps can be taken to mitigate the leak or to repair it. If you have many sinkholes behind the bulkhead it might be time for a major repair. If you just have a couple, there are some steps you can take to put off the major repair for a while. The first thing you have to do is locate the hole or gap. Once you find it, here is what you do.

1. Dig behind the bulkhead until you expose the entire hole or gap.

2. Bring in some rocks that are larger than the hole, so they will not fall through. If this hole is very large, you may try to use larger rock at first and then smaller rock on top. Add just enough rock to cover the entire hole.

3. Cover the rock with filter cloth, also called “sewer paper”. Filter cloth comes in a roll and looks like a coffee filter. It is available at most building supply stores.

4. Next cover over the filter cloth and rock with dirt. Bring the level of dirt all the way to the top of the bulkhead.

This process will allow the water to flow out through the hole and not carry the dirt with it. The hole is still there but this repair will last until the bulkhead deteriorates to the point that it needs a major repair or replacement.

If you have many sinkholes behind the bulkhead but the piles and waler seem to be in good shape then you need to perform a major repair. This happens when marine worms eat out the wood sheeting, usually near the mudline, and the sheeting is no longer sealing the dirt. At this point, you need a new dirt seal. This is a major repair and needs to be performed by a licensed professional. Here is how it is done.

1. All the dirt is dug out from behind the bulkhead.

2. The tie-back rods are cut and removed

3. New vinyl sheeting is driven behind the old wooden bulkhead sheeting forming a new seal.

4. New Tie-back rods are placed to anchor the wall

5. The dirt is replaced behind the wall.

All of these steps are necessary, do not let your contractor take short-cuts. Some contractors will not remove the whole tie-back rod and replace it. Instead, they will clamp or weld a new end of the existing rod. The weld is not galvanized and will start rusting immediately. Clamping on a new rod is not as strong as a solid rod. Also, if the wood sheeting is old enough to be rotted out, then the rod may be almost rusted through in some places, better safe than sorry.

We have also seen some repairs where the contractor or homeowner has placed new vinyl sheeting in front of the old bulkhead and filled the gap with dirt. The new sheeting is bolted to the outside of the old rotting wooden bulkhead. This may seem like a solution, but the wood bulkhead is going to continue to rot, and the bolts are going to pull out eventually, or the dirt is going to put some pressure on the new vinyl and pull the bolts through the vinyl. This is a very short-term type of repair and cost about the same as doing it right.

Bulkhead leaning out

Another major problem that I see with all types of bulkheads is, leaning out. This can happen to concrete, wood, and vinyl bulkheads and is an indication that some or all the tie-back rods have rotted out. If the piles, walers, and sheeting all look fine, but the bulkhead is leaning out, your rods are gone. This problem is completely repairable but must be done by a licensed professional. If you do not fix this problem quickly, your bulkhead will completely fail and fall over. There is also a choice you have to make which will affect the cost of the repair. Do you want to just stabilize the bulkhead, or do you want to “pull” the bulkhead back into its original position?

Another major problem that I see with all types of bulkheads is, leaning out. This can happen to concrete, wood, and vinyl bulkheads and is an indication that some or all the tie-back rods have rotted out. If the piles, walers, and sheeting all look fine, but the bulkhead is leaning out, your rods are gone. This problem is completely repairable but must be done by a licensed professional. If you do not fix this problem quickly, your bulkhead will completely fail and fall over. There is also a choice you have to make which will affect the cost of the repair. Do you want to just stabilize the bulkhead, or do you want to “pull” the bulkhead back into its original position?

The steps to stabilize the bulkhead and prevent further lean or collapse of the bulkhead depends on the type of bulkhead

For Concrete

1. Drive a new wall pile in front of the weep hole in the concrete sheeting

2. Dig a trench behind the bulkhead for a new tie-back rod

3. Drive a new deadman pile

4. Install new rod though new wall pile and deadman and tighten.

For wood or vinyl

1. Dig a trench behind the bulkhead to expose broken rod

2. Remove old rod

3. Inspect deadman and install a new one if necessary

4. Install new rod and tighten

In addition to the steps above, if you want to “pull” the bulkhead back to its original position you must dig all the dirt out from behind the bulkhead so that the wall can be pulled back. You must relieve the pressure of the dirt from behind the bulkhead to move it back into place. Obviously, the labor of the digging and pulling on the wall will add to the cost of the repair.

We have seen many other types of “repairs”, most are very short term (like the one below). There is always a right way and a wrong way, usually very little difference in cost between the two. Give us a call for a Free Estimate.